The History of BIONOT

Before the establishment of BIONOT, during the 1950s, the mechanic Ioannis Nottas decided to specialize in the construction of agricultural machinery, including hydraulic tipping platforms, threshing machines, and various custom-built equipment.

Driven by his passion for the craft and a desire to gain experience, he moved to Germany in the mid-1950s, where he spent three years learning and practicing in leading companies. Equipped with valuable knowledge of German engineering standards and hands-on experience, he returned to Greece.

His entrepreneurial foresight led him, by the late 1950s, to follow the trends of the era while addressing the specific needs of his region in Ammoudia, Serres.

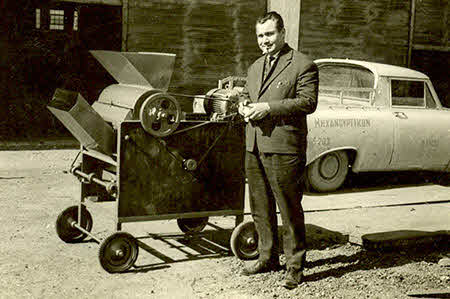

By the early 1960s, Ioannis Nottas built his first peanut (Arachis) sheller, marking the beginning of his activity in the nut processing machinery sector and effectively founding BIONOT, based in Ilioupoli, Thessaloniki.

The impeccable build quality and pioneering ideas of BIONOT quickly gained recognition throughout Greece. This led to a steady flow of orders for various nut processing equipment, primarily serving the primary sector, while also making significant inroads into the secondary sector.

During the 1970s, with the collaboration of his son, Ilias Nottas, BIONOT designed, improved, and modernized many of its already successful machinery models, aiming for greater efficiency and safety.

Later in the decade, as the industrial sector in Greece grew, BIONOT relocated to a new privately-owned facility in Drymos, just outside Thessaloniki. The new premises included modern buildings on a total plot area of 8,000 m², providing the space needed for further growth and innovation.

Drawing on extensive expertise and a highly trained team, along with the contribution of Ilias Nottas, now a qualified mechanical engineer, BIONOT designed and manufactured a wide range of nut processing machinery for both the primary and secondary sectors. In 1974, the company built the almond peeler, a product celebrated for its efficiency and compact, robust design. In 1975, the NOT 78 rotary roasting oven for coffee beans and seeds was introduced, an evolution of the 1960 NOT 60 model. In 1976, the SA418 almond sheller was improved and adapted to meet contemporary needs. In 1979, the LF 500 hazelnut blanching machine was developed, offering excellent performance in a compact size.

With the active involvement of Ilias Nottas, son of Ioannis Nottas, along with new ideas and the company’s expansion into the secondary sector, BIONOT entered the 1980s with outward-looking goals and a broader range of machinery. One of Ilias Nottas’ first innovations was the development of a nut drying machine in 1981, marking a significant step in the company’s growth and product diversification.

The year 1985 marks one of the most pivotal moments in BIONOT’s history. It was the year when Ilias Nottas, through innovation, designed and built the LION 85 hot-air dosing oven entirely from scratch. This machine became the company’s best-selling product, even today, featuring a registered patent and outstanding performance. The success of the LION 85 provided BIONOT with the foundation for global expansion and international recognition.

Growth and Global Expansion in the 1990s During the 1990s, coupled with continuous participation in international exhibitions, BIONOT aimed to establish a strong foundation for its position in the global nut processing machinery market. A key strategic move was the expansion of the existing facility and the creation of additional support areas, designed to meet the demands of production for a large-scale industrial operation. In 1991, keeping pace with industry trends, BIONOT developed the SRB peanut blanching machine. By 1996, responding to growing industrial demand in nut processing, the company introduced the NOT 96 automatic roasting line. In 1998, the first NHL 40 hot-air dosing oven was launched, specifically designed for small and medium-sized nut processing enterprises. Investing in new organizational technologies, expanding operations worldwide, and continually pursuing new challenges, BIONOT grew rapidly, establishing an active customer base in over 40 countries and forging partnerships that continue to this day.

The Turn of the Millennium

The dawn of the new millennium was marked by the rapid expansion of information technology and information systems across all sectors. Having already invested in state-of-the-art equipment and maintaining, since 1996, one of the first websites in the industry worldwide, BIONOT undertook significant technological upgrades, spanning from design processes to the production of machinery.

Modern Advancements in the 2000s

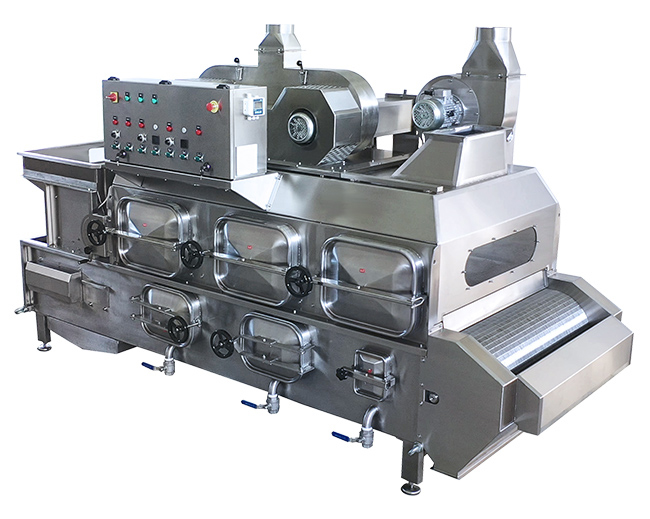

Today, BIONOT manufactures machinery that is even more efficient, functional, safe, eco-friendly, and tailored to the specific needs of each customer, serving both the primary and secondary nut processing sectors. With the growing demand for continuous production, BIONOT introduced the NOT 2000 flow oven in the early 2000s, alongside a wide range of peripheral equipment for flow, transport, sorting, and cooling. These solutions can be combined to meet any production requirement, regardless of scale.

Recent Achievements and Global Reach

Passion, experience, and expertise have sustained BIONOT’s successful trajectory, even during periods of global and local economic challenges. In 2010, BIONOT introduced the NOT 110 dosing oven, designed to roast sesame and similar products with outstanding results. In 2012, the AF 1000 peanut cracking, sorting, and storage line was developed. By the end of 2017, BIONOT successfully met an international competition challenge by manufacturing the NOT 217 walnut cracking and sorting line. Today, with a strong customer-focused approach and ongoing support in expertise, training, and service, BIONOT continues to invest in research, modernization, and the development of high-quality machinery. BIONOT exports to over 80 countries worldwide, maintaining a consistent growth trajectory. With over 60 years of history and experience, the company stands as a testament to reliability, quality, and innovation.

Resilience and Innovation During the COVID-19 Pandemic

During the challenging years of the COVID-19 pandemic, BIONOT not only adapted to the new conditions but also strategically leveraged this period for growth. Despite the obstacles, the company viewed the crisis as an opportunity for further innovation and development.

With the support of its skilled and specialized team, BIONOT focused on research and development of new technologies and products to meet the evolving needs of the market. This period allowed the company to invest in new ideas and strengthen its capabilities, while ensuring workplace safety and retaining its specialized workforce.

The outcome of this strategic approach was the creation of innovative solutions that further solidified BIONOT’s position in the nut and food processing industry. Even during times of crisis, the company has demonstrated its unwavering commitment to innovation, excellence, and reliability, remaining a leading global player in its field.

Entering a New Generation

Building on a solid foundation of past experience and achievements, guided by present-day expertise and specialization, continuously researching the evolution of our equipment, and with the trust of over 3,000 customers, BIONOT now enters its third generation with boundless ideas and passion.

Envisioning an even more productive future, we aim to deliver high-quality, state-of-the-art products that provide significant benefits to the end user.

BIONOT continues its dynamic journey forward, committed to innovation, excellence, and customer satisfaction.